Jan. 15, 2025

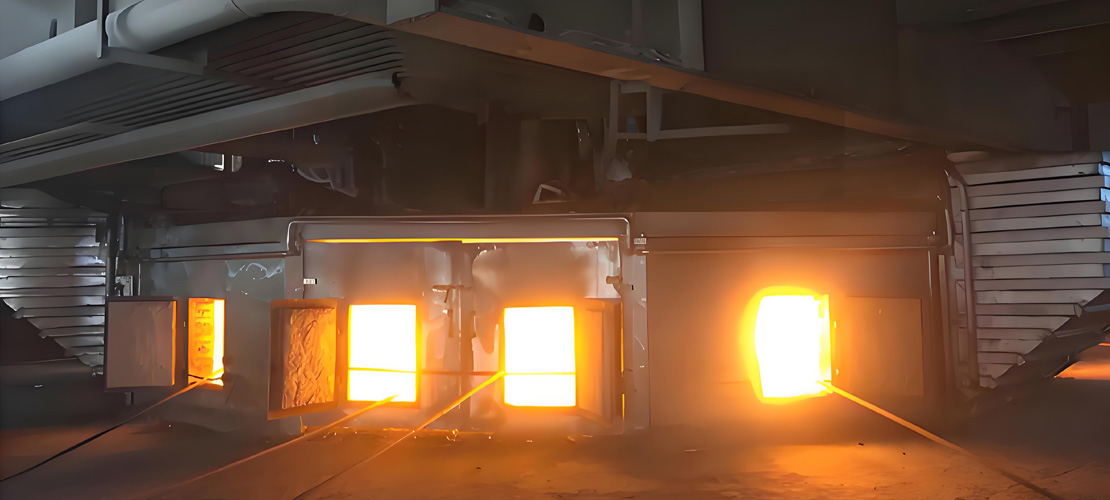

Three days before Submerged Arc Furnace cleaning, gradually lengthen the working end of the electrode to 1900~2000mm. Stop gas purification before power outage.

Before submerged arc furnace cleaning, the Si content of the alloy is controlled at more than 17%, and the alkalinity is slightly increased. After the material pipe is empty, the material level is slightly lowered and 5~8t of white ash for furnace cleaning is added to the furnace.

If the equipment allows, the melting time can be appropriately extended, and the iron outlets on both sides are opened at the same time when iron is tapped. When the furnace charge drops below the material pipe shutter, the shutter is closed and sealed with white ash.

During power outages, the small material bin on the furnace and the corresponding large material bin should be empty to prepare for timely material change when the furnace is opened and prevent the material bin from freezing in winter, which will affect the next furnace opening.

During the submerged arc furnace production process, submerged arc furnace equipment should be regularly inspected and updated, and power outages within 8~10h are minor repairs. Stop lowering the electrode 4 hours before power outage, handle the electrode hanging material accident before power outage, and shut down the power after the furnace is out. After the power outage, appropriately reduce the copper tile cooling water flow, and place the electrode in the middle and lower limit position after the power outage.

The Si content of the last furnace of manganese silicon alloy before power outage is controlled to be no less than 17%. After the power outage, try to maintain the furnace temperature. First stop the gas purification and then open the operation hole. After destroying the gas in the furnace, close the flue flap and the operation hole.

If the power outage time exceeds 4 hours, move the electrode once to prevent the furnace charge and the electrode from sticking together.

Temporary hot stop: During the submerged arc furnace production process, if a temporary power outage is required for some reason, the power outage event is close to minor repairs. In principle, it is carried out according to the minor repair power outage. For those with a shorter power outage time, it is only necessary to lift the electrode slightly to shut down.

Latest News

Principle of Steel Shell Medium Frequency Induction Furnace

Jan. 17, 2025

Characteristics of DC Submerged Arc Furnace For Smelting

Jan. 15, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province