Jan. 29, 2025

In view of the power consumption problem generated during the entire refining furnace production process, it is necessary to adopt specific and feasible methods to optimize each link, so as to continuously reduce the power consumption of the refining furnace.

Reduce the heat dissipation of the ladle during transportation: make good ladle insulation materials to enhance the insulation effect and reduce the heat loss of the ladle slag surface; at the same time, through reasonable production arrangements, improve the qualified rate of the molten steel composition arriving at the station to shorten the waiting time.

Appropriately increase and stabilize the tapping temperature of the electric furnace, which creates good conditions for increasing and stabilizing the refining temperature of molten steel in the refining furnace. On the one hand, increasing the temperature of molten steel entering the station shortens the waiting time, and on the other hand, increases the tapping temperature of the electric furnace, ultimately reducing the power consumption of the refining furnace. According to statistics, while strengthening management, the average superheat of each steel grade decreased by about 2°C during the same period.

This plant smelts heavy steel ingots, so it needs to cast steel from two refining furnaces together. In this way, one furnace needs to wait for the next furnace to cast steel before casting. Therefore, it is necessary to speed up the refining speed of the steel in the next furnace behind the refining furnace, thereby shortening the refining time.

The operation level of the refining furnace operator will also affect the power consumption. By strengthening the professional skills training of the workers, improving the workers' operation level, formulating a reasonable process system, strengthening the scheduling management and technical personnel tracking management, and improving the assessment system, it can not only ensure that the steel is produced according to the plan, but also reduce the operation time from the electric furnace to the refining furnace by 10 minutes.

Energy conservation and emission reduction are the problems that must be solved in the current production and operation of steel smelting enterprises. Through effective technical methods to optimize and transform the production process and improve the energy utilization efficiency of the enterprise in the production process, it can have a direct impact on the enterprise's operating cost control and product quality.

Latest News

Latest Products

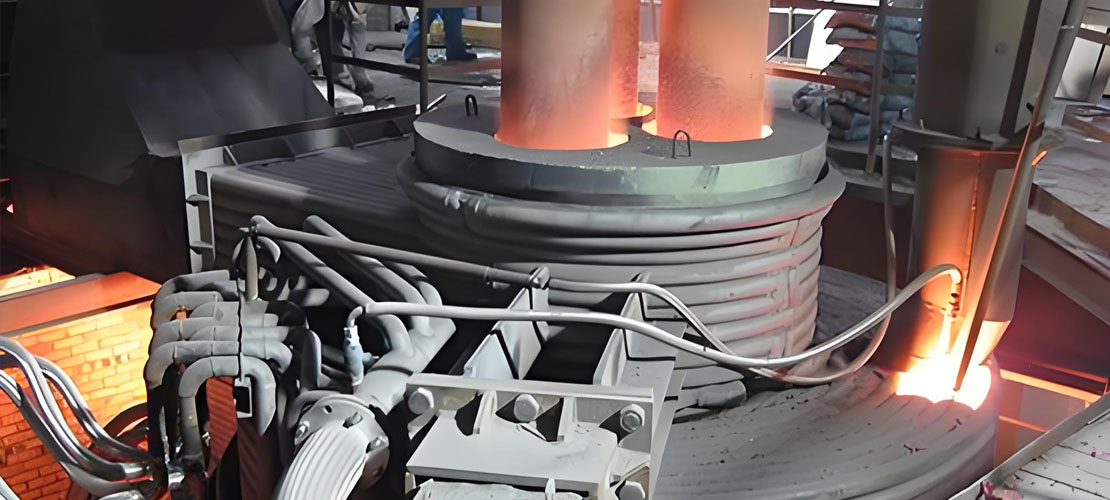

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province