Jan. 28, 2025

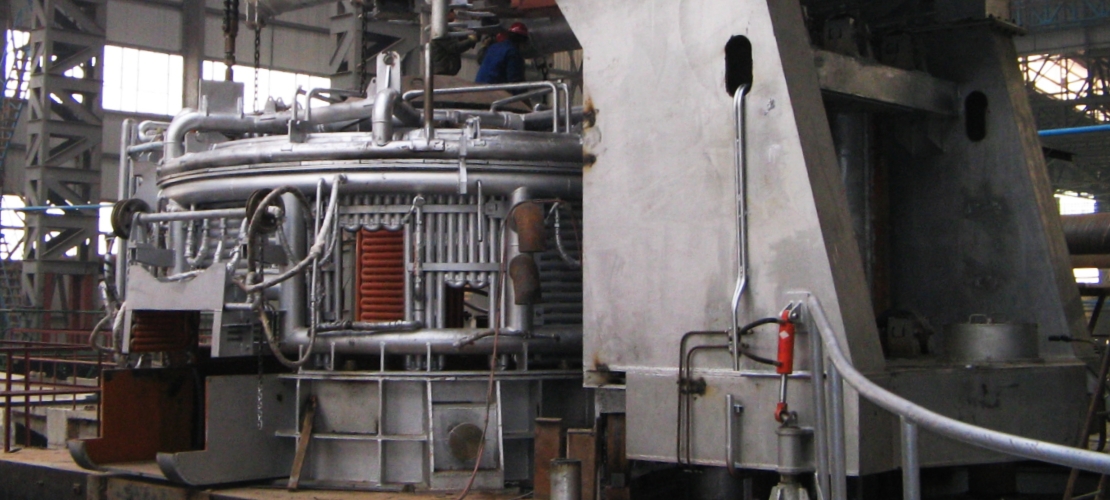

The electric arc furnace water cooling systems mainly used to cool the furnace body and furnace cover during the smelting process of the electric arc furnaces.

The system usually includes a water supply pipeline, which is directly connected to the tap water supply pipe to ensure that the electric arc furnace can continuously obtain cooling water during the smelting process.

The water pump is the core component of the water cooling system, and its performance directly affects the cooling effect of the entire system. In addition, the pipeline layout also has a great influence on the cooling effect of the water cooling system.

The electrode holder, electrode sealing ring, upper part of the furnace shell, furnace door cover, furnace door frame, furnace cover ring, furnace wall, furnace cover and other parts of the electric arc furnace are usually cooled with water to increase the service life and improve the working conditions in front of the furnace.

The cooling water system includes a bracket, a water storage tank, a water inlet, a water outlet and corresponding connecting pipes. The design is relatively simple and easy to install and maintain.

The cylindrical tank of the water tank is placed horizontally at the bearing end of the bracket, with the water inlet on its side and the water outlet at the bottom of the arc, and the height of the water inlet is higher than the water outlet. This design allows the water flow to circulate naturally and improves the cooling efficiency.

The water supply pipe is directly connected to the water supply system of the electric arc furnace and connected to the water outlet of the water tank to ensure a stable water source during normal production.

A certain amount of water is always maintained in the water tank to provide cooling water quickly when there is a water outage.

The electric arc furnace water cooling systems effectively reduces the temperature of the electric furnace by continuously circulating cooling water to prevent the furnace body from overheating, thereby ensuring the safety of the equipment.

Once the water supply is interrupted, the backup water in the water tank can be put into use immediately to ensure that the furnace body can still be cooled in an emergency, avoiding unexpected shutdown and equipment damage.

The water cooling system can effectively prevent the overheating of the electric arc furnace caused by insufficient water supply, ensure the normal operation of the electric arc furnace, and reduce safety hazards.

Maintaining a good cooling effect not only increases the service life of the equipment, but also helps to improve the production efficiency of the electric arc furnace.

Through these characteristics and functions, it is known that the electric arc furnace water cooling systems plays a vital role in the smelting process. It ensures the normal production of the electric arc furnace and realizes the safe production of the electric arc furnace.

If you have other questions about the electric furnace cooling water system or need further detailed information, please feel free to contact us.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province