Jan. 21, 2025

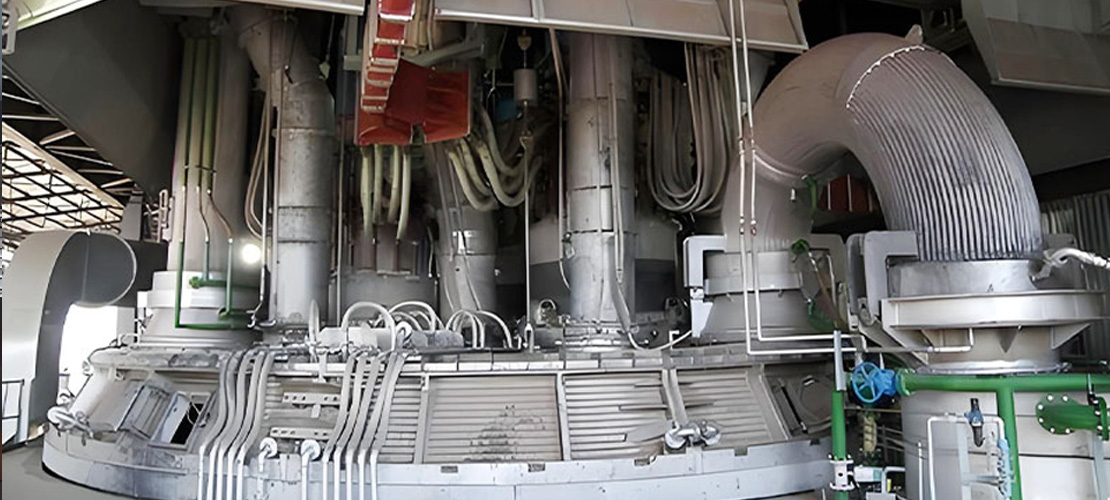

Submerged arc furnace pig iron making is a way of smelting pig iron without blast furnace. Under the premise of guaranteed power supply, the reducing agent required for ironmaking in an submerged arc furnace can be easily solved.

Submerged arc furnace pig iron making can use semi-coke, semi-coke and coal instead of coke as reducing agent.

The closed pig iron submerged arc furnace adopts new technology and new equipment for hot charging, which can save energy and reduce consumption, and can achieve good benefits.

After the iron concentrate comes out of the sintering machine, it enters the insulation bin, and the hot material enters the insulation bell through the chute, and the weighed reducing agent and lime are added at the same time. The insulation bell is transported to the main plant, and the insulation bell is lifted to the furnace top silo platform by a crane, and then lifted to the furnace top silo, and the hot material is automatically unloaded into the furnace top silo.

Using this technology, compared with cold material entering the furnace, the power consumption per ton of pig iron is reduced by about 300 kW.h/t.

Iron concentrate sintered ore, coal, and lime are automatically batched and fed into the transfer bin on the top silo platform through a mixing belt conveyor and a high-angle belt conveyor. The hot materials are automatically unloaded into the top silo through an electric vibrating feeder and a transfer belt conveyor.

Batching, Loading, Feeding, and Unloading are all PLC-controlled.

Two sets of iron and slag tapping ports are used, one for use and one for backup. Two ladles are set in front of each set of iron and slag tapping ports.

Using this technology, the furnace will not be shut down due to nozzle failure. It can also avoid being forced to reduce load operation due to nozzle failure or reduced number of tapping times.

The use of a combined gripper can improve the conductivity of the electrode.

It can effectively solve the problem of electrode roasting, and will not cause poor contact of conductive components due to the non-round electrode barrel.

The three-phase short network is arranged at 120°, and the copper tubes are connected in parallel in the same direction. Copper tubes and water-cooled cables use low current density parameters.

Reduce the active power loss of the short network, increase the furnace load, and reduce the imbalance of the three-phase electrode power.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province