Dec. 27, 2024

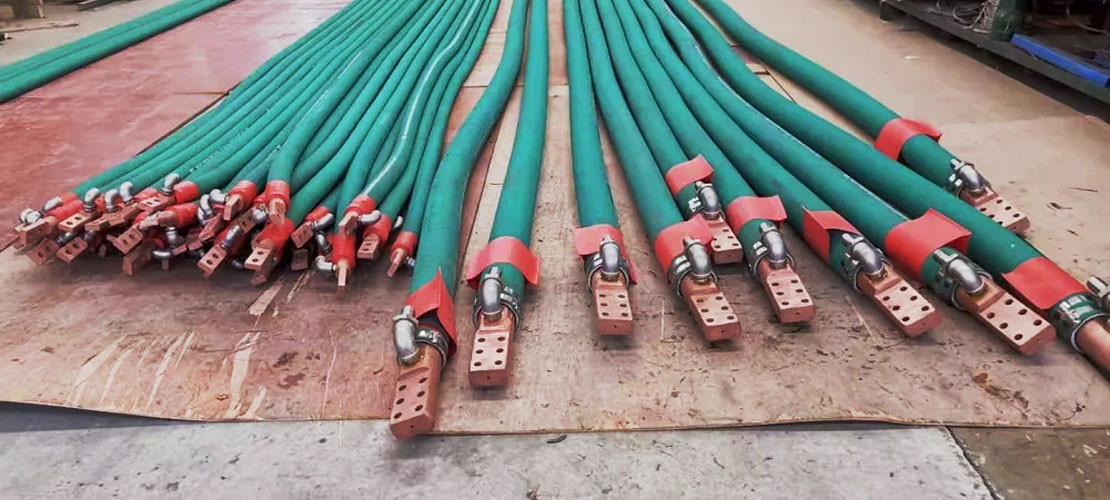

The Induction Furnace Water-Cooled Cable cross-section is in the range of 25 to 6000 square millimeters; the length is in the range of 0.3 to 70 meters, which meets the national standard GB.

1. The electrode (also called cable head) has no contact, no welding point, and no welding seam. It is made of a whole copper rod on a CNC lathe and milling machine. It is beautiful and durable; the connection between the electrode and the wire is cold extruded, which does not damage the wire and has low resistance.

2. For the outer sleeve, a high-quality rubber hose is selected, with water pressure resistance > 0.8MPA and breakdown voltage resistance higher than 3000V. There is also a flame-retardant outer sleeve for users to choose from on special occasions;

3. For the fastening of the electrode and the outer sleeve, copper clamps are used for cables below 500mm 2, and 1Cr18Ni9Ti clamps are used for other cables. They are non-magnetic and rust-free; they are extruded and fastened with large hydraulic equipment, which is beautiful, durable, and has a good sealing effect;

4. The soft wire is processed with fine enameled wire on a special winding machine. Soft, small bending radius, large effective cross-section;

5. Use enameled wire as indution furnace water-cooled cable, high power transmission efficiency. Because each enameled wire is insulated, it conducts medium-frequency and high-frequency currents, and there is no surface skin effect. Compared with other water-cooled cables with the same cross-section, it generates less heat when the same current passes;

6. Use enameled wire as the conductor of induction furnace water-cooled cable to increase the service life of water-cooled cable. Because the conductor of water-cooled cable is immersed in water for a long time, the working environment is very harsh.

In the past, we used copper bare wire to make induction furnace water-cooled cable. When the water-cooled cable was used for a period of time, the cable jacket was opened, and a layer of green copper rust could be seen on the surface of the conductor. Later, we switched to enameled wire for water-cooled cable, because the enameled wire has a paint film protective layer, which can play an anti-corrosion role.

Users reported that the service life of induction furnace water-cooled cables made of enameled wire is 1.5 to 2 times that of copper bare wire.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province