Feb. 20, 2025

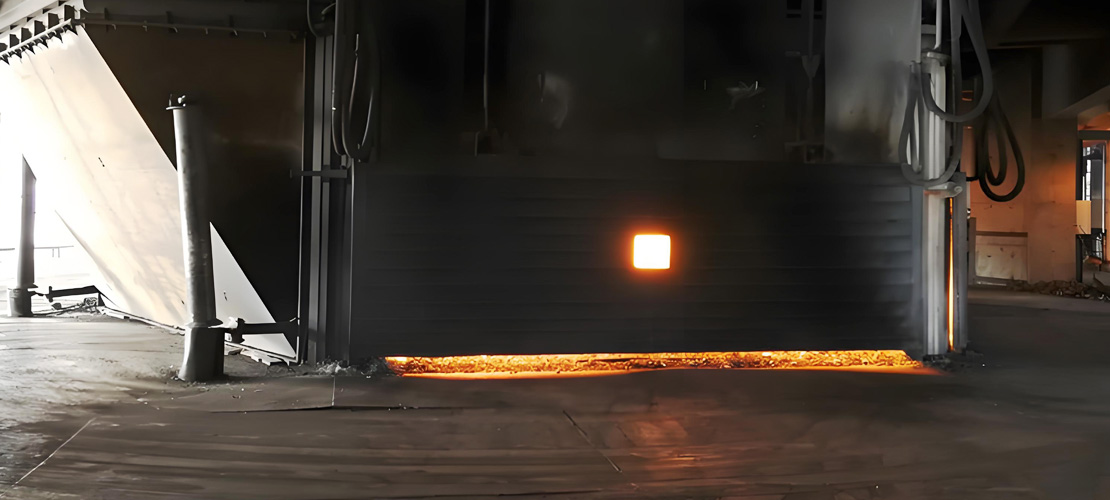

The new energy-saving industrial silicon submerged arc furnace is an industrial silicon smelting equipment that adopts advanced technologies such as large furnace type, sealed SAF furnace type, waste heat utilization and improved short-net structure, improved transformer performance and electrical parameters, etc., aiming to reduce energy consumption and improve smelting efficiency. It is an important tool in the metallurgical industry.

The design fully utilizes the skin effect characteristics of large current conductors, and three small graphite electrodes are sintered together with electrode paste. During the production process, they are continuously pressed and removed according to needs. It not only has a huge power saving effect, but also has a very low electrode cost advantage.

Fully absorb the advantages and disadvantages of the combined gripper and the copper tile gripper, and use the two structures together. It not only solves the problem of poor contact of the copper tile structure leading to high current introduction, but also ensures automatic electrode shelling to ensure product quality.

The designed arched smoke hood has an octagonal structure and is made of stainless steel, making full use of the flow principle of hot flue gas. The electrode can be lifted above the smoke hood for maintenance, reducing the maintenance intensity and shortening the maintenance time. Moreover, the smoke collection effect (environmental protection effect) is very good, and it is of great significance to improve the quality of silicon powder, a by-product of industrial silicon.

Provide a special internal design structure to change the traditional industrial silicon production using high-voltage power distribution process, and use up to 24-36 groups of secondary outlet terminals and specially designed short net structure, the energy saving effect is very significant.

The lower part of the material pipe adopts a spring-type spiral tube structure, the gate valve adopts a large inclination angle (three-position solenoid valve control), and the material bin is layered.

The design scheme of masonry that breaks the conventional mindset is adopted. Only 400-600mm high annular carbon bricks are used for furnace lining masonry, and special treatment is made on the high-aluminum bricks on the upper part of the annular carbon bricks, which not only ensures the safety of the furnace lining, but also has great practical significance for deep insertion of electrodes and preventing the rise of the furnace bottom.

Other proprietary technologies such as reasonable geometric and electrical configuration dimensions, guide mechanism of electrode column, special-shaped brick sealing of electrode and smoke hood, loading and unloading system, maintenance platform, equipment water cooling, annular low-carbon brick furnace building, etc. are of great significance to improving the technical equipment level of industrial silicon production at home and abroad, and play a huge demonstration role in the development of the industry in terms of equipment operation rate and energy conservation and emission reduction.

The only domestic enterprises that use composite electrodes for industrial silicon production are Henan Luoyang Shengyang Silicon Technology Co., Ltd., which has two 39MVA industrial silicon furnaces, and Henan Dengdian Group, which has two 25.5MVA industrial silicon furnaces (one in production and one under construction). However, both enterprises are located in the Central Plains, where electricity prices are high, and do not have competitive advantages over low-price areas in the northwest and southwest. The former uses a composite electrode structure with a single graphite electrode and a copper tile holder, while the latter uses a composite electrode with three graphite electrodes and a combined holder (the one under construction uses a composite holder). Luoyang's industrial silicon furnace only has an electrode cost advantage, but not an electricity saving advantage. Dengdian Group not only has an electrode cost advantage and, but also has a greater electricity saving advantage.

The composite electrode is a composite electrode made of a special electrode paste and a graphite (or carbon) electrode, which is sintered in the electrode shell to supply power to the furnace and realize shelling to produce high-grade industrial silicon. This type of electrode is regularly shelled according to production consumption and process requirements, and the electrode shell is not consumed or is consumed in very small quantities. Its advantages are:

(1) Power saving: The power consumption of a ton of silicon smelting in a large industrial silicon furnace using carbon electrodes in China is generally between 13,000 and 14,000 degrees, while the use of composite electrodes can reach less than 12,000 degrees.

(2) Electrode cost: The cost of a ton of silicon electrode in a large industrial silicon furnace using carbon electrodes (diameter above 1,000 mm) in China is between 1,800 and 2,200 yuan, while the use of composite electrodes is less than 1,000 yuan.

(3) Raw materials: The composite electrode makes full use of the skin effect of the large current conductor to allow the load to be directly sent to the bottom of the furnace. There is almost no sparking during the production process, and the raw material consumption per ton of silicon is very low.

(4) Equipment operation rate: After the composite electrode is started, there will be almost no electrode accidents. Even if an electrode accident occurs, production can be started directly without electrode roasting, and the equipment operation rate is extremely high.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province