Apr. 12, 2025

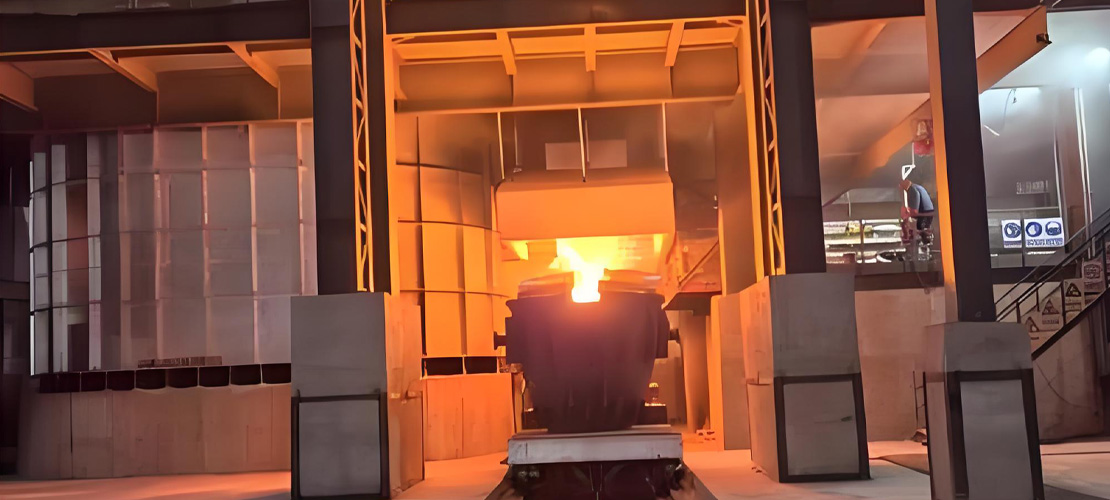

This article primarily discusses the process of producing high-silicon silicon manganese in large closed submerged arc furnace. High-silicon silicon manganese is a deep-processed product of ordinary silicon manganese, characterized by low impurity content, particularly low levels of C, S, and P. Traditionally, open or semi-closed furnaces have been used for its production. The principle of producing high-silicon silicon manganese in closed furnaces is similar to that of ordinary silicon manganese, with the main chemical reaction being the formation of MnSi through the reduction of silicon by carbon. The challenges in producing high-silicon silicon manganese in large closed furnaces include persistently high electrode consumption, high temperatures at the furnace opening, significant reactive power losses, low power factor, high alloy pig iron temperatures, extended tapping times, severe oxidation and erosion of the tapping hole, high furnace temperatures, high emissions of flue gas and dust, and increased load on the flue gas and coke oven gas purification systems. The conditions for producing high-silicon silicon manganese in large closed furnaces involve the alloy composition and grade, rational raw material blending, furnace charge grade, chemical and physical properties of coke, and slag type selection. The particle size of coke should be chosen based on the furnace capacity and coke variety. Slag types include magnesium-based, calcium-based, and aluminum-based slags, with selection considering comprehensive utilization and cost reduction.

High silicon silicon-manganese is a deep-processed product of ordinary silicon-manganese. Due to its low impurity content, especially low C, low S, and low P products, traditional smelting electric furnaces for high silicon silicon-manganese are open or semi-closed furnaces.

The production principle of high silicon silicon-manganese alloy is the same as that of smelting ordinary silicon-manganese alloy. The main chemical reaction formula is as follows:

(MnO)+(1+X)C=[MnCx]+CO

(SiO2)+2C=[Si]+2CO

(SiO2)+2C+[MnSiCx]=MnSiCx+2CO

The difference between high silicon manganese and ordinary silicon manganese alloys lies in their silicon content, which results in different forms of carbide destruction. When [Si] < 23.5%, the carbide destruction takes the form of: (MnFe)7C3 + 7Si = (MnFe)Si + 3C

When [Si]>23.5%, the form of silicon disrupting carbides is:

(MnFe)7C3+10Si=7(MnFe)Si+3SiC

The silicon produced through carbon reduction combines with manganese to form MnSi, thereby improving the reduction conditions. The higher the silicon content in the alloy, the higher the starting temperature for SiO2 reduction. When producing silicon-manganese with a silicon content of 14%, the starting temperature for SiO2 reduction is 1475°C; when producing silicon-manganese with a silicon content of 20%, the starting temperature for SiO2 reduction is 1490°C; and when producing high-silicon silicon-manganese with a silicon content of 28%, the starting temperature for SiO2 reduction is 1510°C.

2.1 The electrode remains high, making it difficult to insert, and the sparking is severe; the temperature at the furnace mouth is high, causing significant equipment damage; there is a large reactive power loss and a low power factor.

2.2 High-silicon silicon-manganese alloy has a high temperature in molten iron, requires a long tapping time, and is prone to severe oxidation and erosion at the tap hole, which can easily burn through and make maintenance difficult.

2.3 Selection of suitable slag types for high silicon-manganese content.

2.4 The furnace temperature is high, resulting in a large amount of flue gas and dust production, which places a heavy load on the flue and gas purification system.

Latest News

Electric Arc Furnace Cooling System & Components

Apr. 17, 2025

Electric Arc Furnace EAF Steel Production Features

Apr. 16, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province