R&D Team

The R&D technical team has 25 people and the electrical engineer team has 20 people. It includes an innovative team formed by many Chinese metallurgical design experts, well-known technical backbones in the industry, and smelting process expert consultants for steelmaking and ferroalloy companies.

Retired Chief Technical Engineer of the Technical Department of Xi'an Heavy Electric Furnace Manufacturing Plant, a state-owned enterprise under the Ministry of Metallurgy of China.

Factory Address 1: Zhaishang Village, Laodian Town, Huyi District, Xi'an City, Shaanxi Province (Professional Electric Arc Furnace, Submerged Arc Furnace, Refining Furnace, Vacuum Refining Furnace, etc. Manufacturing Factory)

Factory Address 2: Western Intelligent Equipment Industrial Park, Zhouzhi County, Xi'an City (Professional Induction Furnace Manufacturing Factory)

60+

Production Team

25+

R&D Technical Team

60+

Electrical Engineer Team

25+

Sales Team

16000+

Plant Area

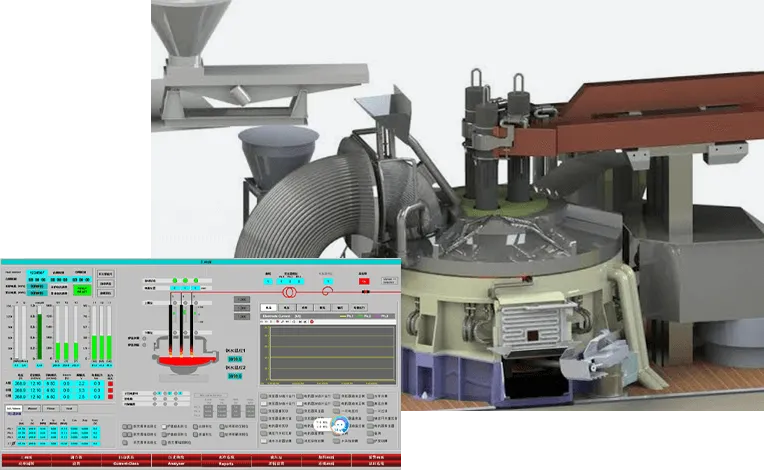

Sanrui Electric Furnace Complete Line of Equipment Adopted Technology

1. Low-voltage dynamic reactive power compensation technology

2. Submerged arc furnace flue gas waste heat utilization technology

3. Integral forged copper tile type bracket electrode system

4. Intelligent electrode automatic adjustment technology

5. Continuous hot feeding technology

6. Continuous cold feeding technology

7. Double-port and double-bag tapping and slag tapping technology

8. The unique waterway design and advanced manufacturing process of the water-cooling protective sleeve

9. Use scrap steel basket to feed materials

10. Copper-steel composite conductive cross arms and large-section water-cooled cables

11. The furnace cover adopts frame type tubular water-cooled furnace cover

12. The furnace structure adopts an integral tilting platform

13. Take out the steel from the tapping chute

14. Discharge slag from slag tank

15. Computer and PLC control, the electrode regulator adopts constant impedance adjustment technology)

16. Use a mobile hood to remove dust

17. Adopt self-consumable furnace door carbon and oxygen gun injection technology to shorten the smelting cycle and reduce power consumption

18. Deoxygenation calculation model

19. Desulfurization and slagging calculation model

20. Component adjustment calculation model

21. Calculation model for temperature rise of molten steel heating

22. Argon blowing stirring calculation model

23. GW series medium frequency melting furnace

24. HQ type precision casting furnace

25. GWL series medium frequency aluminum melting furnace

26. GWT series medium frequency copper melting furnace, vacuum furnace, and other medium frequency copper melting furnace series

27. KGCX, IGBT, KGPS series intermediate frequency power supply

28. Fully enclosed cooling tower, pulse bag dust collector and other intermediate frequency furnace supporting equipment

Quality Control Safety Testing

Drawing Conversion and Task Assignment

The technical department converts the drawings into internal drawings according to the customer's needs and design drawings in combination with internal technical experience, and issues the drawings and technical requirements to the production workshop through the production task notification. Production plan shall be formulated after confirmation by both parties.

Confirmation of Production Plan and Process

After the production plan is determined, the workshop director and the operator shall confirm the machining process together to ensure compliance and rationality and guarantee the precision and quality of the product.

Material Procurement and Supply

The Procurement Department shall purchase the required materials and accessories from the long-term cooperative suppliers according to the procurement schedule to ensure timely supply to match the total assembly time of production.

General Assembly and Inspection of Products

After all accessories and machined parts are in place, the workshop organizes the general assembly, and the technical director reviews the quality of the parts. Upon the completion of final assembly, the Production Department and the Technical Department shall jointly inspect the product quality, focusing on the accuracy of overall dimensions.

Performance Test and Report

After passing the appearance test, the technical personnel shall carry out the product performance test, especially the pressure test of the water-cooled cable required by the customer. After passing the test, the test report shall be generated and archived.

Production Equipment

Sanrui is well experience in design, manufacturing, installation, commissioning of steelmaking furnace process equipment. Send us your project details inquiry and our team of engineers will design a metallurgical furnace equipment system solution from A to Z based on your needs.

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province